Types of Feed Mechanism:

- Drop feed mechanism.

- Differential bottom feed mechanism.

- Adjustable top feed mechanism.

- Needle feed mechanism.

- Unison feed mechanism.

- Puller feed m mechanism.

1. Drop feed mechanism

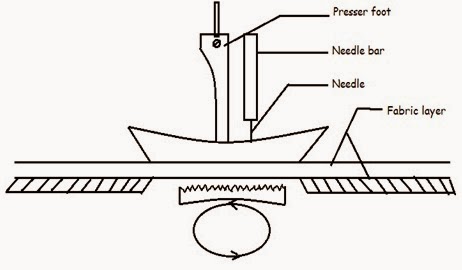

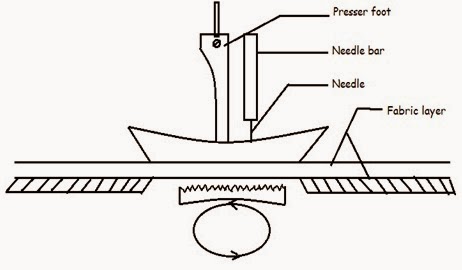

The drop feed mechanism is commonly found in domestic sewing machines and a majority of industrial sewing machines. Also known as the regular feed mechanism, the drop feed mechanism involves the movement of serrated metal strips known as feed dogs, which are found in slots in a sewing machine’s needle plate. As the needle is retracted from the fabric, the feed dogs underneath drag the fabric or material horizontally in order to move the workpiece.

- The simplest feed system of sewing of sewing machine is still common.

- Also known as a regular feed.

- The main components of the drop feed mechanism are.

|

| Fig: Drop feed mechanism |

Problems of Drop Feed:

- When two plies fabrics are sewn- the lower ply moves forward by the help of the feed dog but foot. So two pieces of fabric can not move forward at the same speed. As a result, the lower ply is more fed than the upper ply. This is called ply shifting/differential feeding pucker/feeding pucker. Sometimes roping occurred during the making of them for ply shifting.

- It the pitch of the stitch is the same pitch as the feeding dog the same then the fabric may be damaged for repeating contact of the feed dog's teeth & fabric at the same place.

Remedies:

- Silk is less of the operator.

- Needle manual technique such that, stitch length & pitch of feed dog should not be equal.

2. Differential bottom feed mechanism.

Sewing machines that use a differential feed mechanism have two independent sets of feed dogs. These feeds dogs can be manipulated so that the material or fabric around the needle can be stretched or compressed as needed.

- Modification of drop feed system.

- In the feed mechanism, the feed dog consists of 2 sections one at the back & one at the front of the needle.

- The mechanism of each section of the feed dog is like the drop feed system. But the speed of each part can be adjusted separately.

- Extensively used for stretchy materials.

|

| Fig: Differential bottom feed mechanism |

- When the speed of the front-feed dog is higher than the back-feed dog. “ The bottom ply is pulled by the back feed dog but this will be overcome by the greater speed of the front feed dog. So less possibility of shifting”.

- When the speed of the front feed dog is less “ we get lacy effect because the feeding speed is greater than the delivery speed”.

- Stretching & gathering of fabric can be done by this system.

3. Adjustable top feed mechanism.

The general arrangement of such top feed systems is that the presser foot is in two sections, one holding the fabric in position while the needle forms the stitch and the other having teeth on the lower side and moving or walking in such a way that the top ply is taken along positively while the needle is out of the material. It can be used in machines for sewing lightweight fabrics without any inter-ply shift. 1- Needle lockstitch machine with automatic thread trimmer having a bottom and variable top feed.

- In the general arrangement, the presser foot is in two sections.

- One holding the fabric in position while the needle forms the stitch and the other having length on the lower side & moving or waking in such a way that the top ply is taken along, positively while the needle is out of the materials.

- In sewing machine, the feed mechanism can be used with both drop feed & differential bottom feed.

- Combination of adjustable feed & differential bottom feed can make top ply gathering or the gathering of bottom ply.

|

| With drop system. |

|

| With differential bottom feed. |

Fig: Adjustable top feed system.

4. Needle feed mechanism

Many industrial sewing machines, especially those that use double needles, use the needle feed mechanism. They rely on the needle itself to act as the primary feeding element that moves or advances the fabric through the feeding zone.

- Another name of the needle feed mechanism is “Compound feed”.

- The needle itself moves forwards & backward.

- The needle penetrates the fabric and enters into the note of the feed dog & for the advanced movement of 1 stitch length of fabric feed dog & needle pass the fame distance at the same time.

- Then the needle rises up & moves to form the next stitch with one step advance.

- Practically useful in bulky sewing situations such as when quilting through the fabric. wadding & for slapping fabrics

- For the change of stitch length, the setting of the bath needle & feed dog should be changed.

|

| Fig: Needle feed mechanism. |

5. Unison feed mechanism.

Unison feed is a further combination of feeding mechanisms that provides needle feed in addition to positive top and bottom feeding. It is valuable in the sewing of especially those with tacky surfaces, and it can achieve seam joining an edge binding without ply shift. It is used for operations on materials that have very low friction coefficients and for operations that are thick and heavy.

- AKA “walking foot system because the presser foot has two independently driven sections; the holding & the holding & the feeding feet.

- Mode by combination of needle feed & positive top & bottom feed.

- In this system, one presser foot is inside the other presser foot & gives movement at different times.

- The inside presser foot & needle are driven at the same time toward the same direction.

- No possibility of ply shifting.

- Suitable for sewing stitch fabric & for bulk seams in heavy-weight materials.

- Normally not so used unless special case.

|

Fig: Unison feed mechanism.

|

6. Puller feed mechanism

Sewing machines with a puller feed mechanism use supporting rollers that grip and pull the fabric or material being sewn. It is useful for sewing large and heavy workpieces like leather upholstery, tents, and car covers.

- Modification of drop feed system.

- A pair of rollers was used.

- These rollers give a pulling motion on the fabric behind the presser foot.

- The top roller is generally driven by the machine whitest the lower one moves due to the control & pressure of the top roller.

- The surface speed of the puller roller is slightly higher than the feed dog speed to presser ply shifting roping.

- Useful in a multi-needle machine specially for W/B making.

|

| Fig: Puller Feed mechanism |

No comments